About the Program

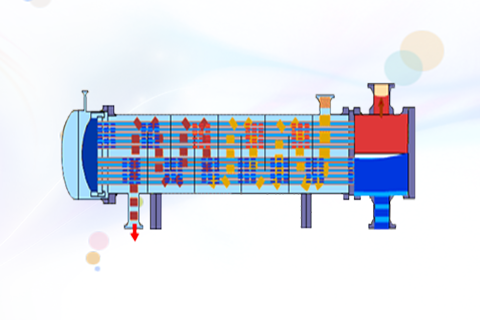

Master the intricacies of process equipment spanning reactors, distillation columns, material handling systems, heat exchange processes, and more. Explore safety considerations, wastewater management, and the critical components of flare systems. Understand the impact of weather on flame behavior and delve into the importance of filters and strainers, alongside safety measures for efficient operation.