About the Program

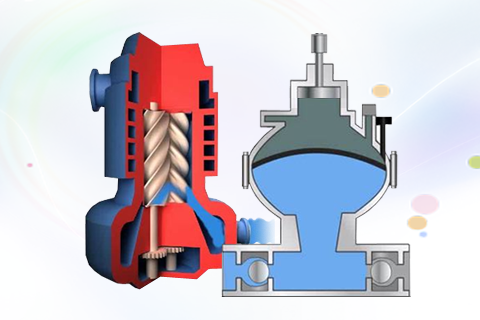

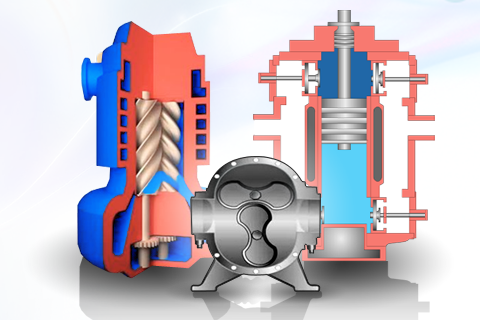

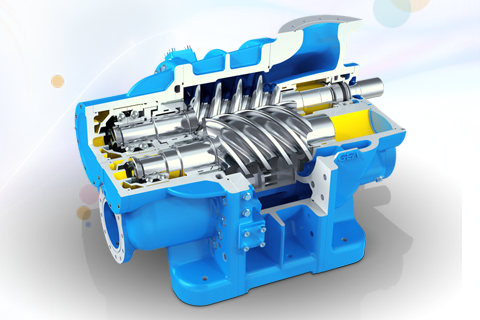

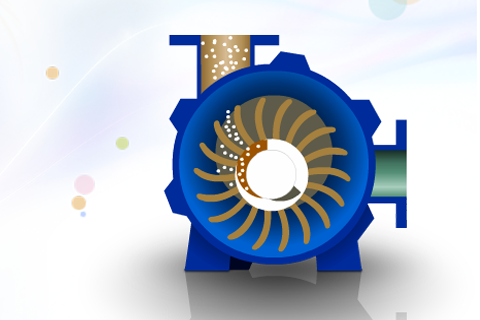

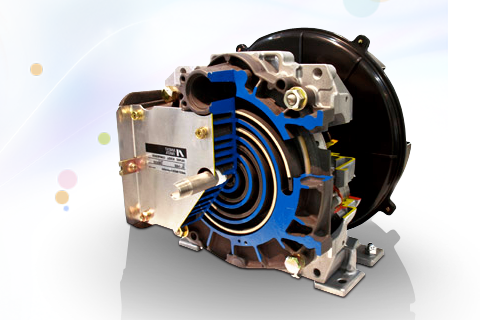

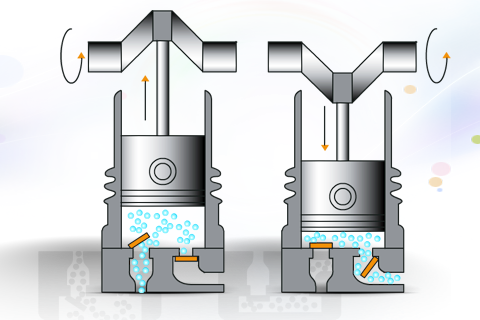

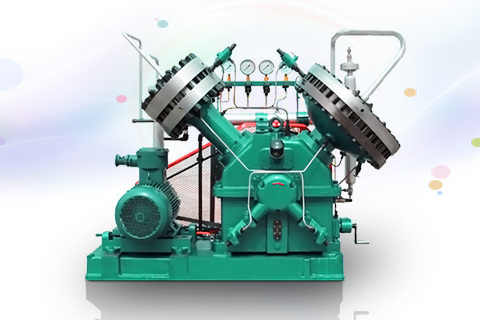

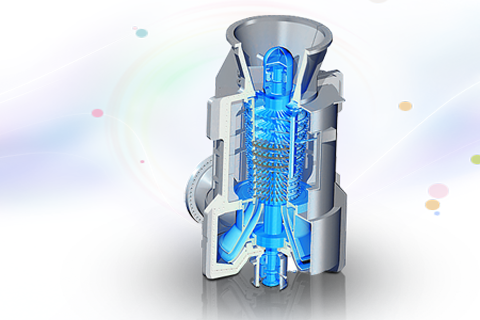

Compressors are integral to the process industry, serving to increase the pressure of gases for various applications. Our program explores different types of compressors, including lobe, screw, liquid ring, scroll, vane, piston, diaphragm, centrifugal, and axial compressors. Learn their principles, key components, advantages, disadvantages, applications, and troubleshooting methods. Gain insights into the diverse range of compressors and understand their roles in industrial processes.